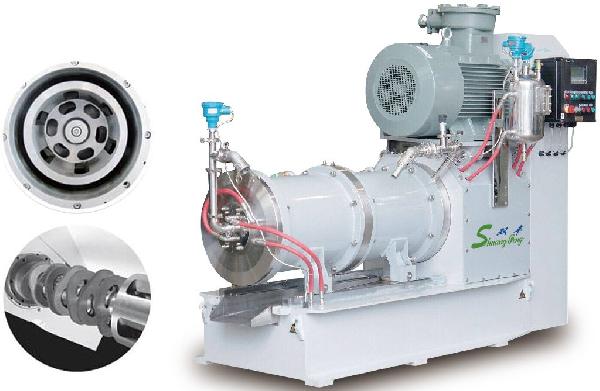

SWD大流量砂磨機

1042

應用領域:選礦設備

產(chǎn)地:江蘇 - 南京

廠家/供應商:江陰市雙豐機械有限公司

咨詢電話::暫無(請說明信息源自“中冶有色技術網(wǎng)”)

SWD大流量砂磨機說明介紹

小腔體,高流量,高產(chǎn)能Smaller process chamber, High flow, High capacity

SWD大流量砂磨機采用新研發(fā)功能部件為你提供更經(jīng)濟的濕法研磨工藝和技術,高效率研磨盤片和超大離心輪及篩網(wǎng)使研磨珠子能更好的分布在研磨腔,利用離心動態(tài)分離式篩網(wǎng)提高流量,研磨珠能安全的分離,甚至在高流量時高效率的分離系統(tǒng)發(fā)揮作用包含下列單元:1.離心輪及篩網(wǎng)和整合的盤片;2.特殊的超大篩網(wǎng)�����。SWD large flow sand mill with new functional components provide wet grinding techniques and more economical for you, high efficiency and large centrifugal wheel grinding disc and the grinding beads screen better distribution in the grinding cavity, split screen to improve the flow by centrifugal separation can be dynamic, secure, even in high traffic separation system high efficiency play a role includes the following units: 1. disc centrifugal wheel and screen and integration; 2. special large screen.

◎ 工藝特性/ Properties of the Process

●排除腔體內無效徑向力 ● Elimination of ineffective radial force in the cavity●可更換各種材質的內腔體 ● Replacement of the inner cavity of various materials●可更換前后端蓋和易磨損備件為耐磨損材質 ● Wear and tear material for wear and wear parts before and after replacement●特殊盤片和軸心設計 ● Special disc and axle center design●離心動態(tài)分離式篩網(wǎng) ● Centrifugal dynamic separation sieve

◎ 優(yōu)勢表現(xiàn)/ Superiority performance

● 介于高能量密度和傳統(tǒng)砂磨機之間的高效率研磨設● High efficiency grinding equipment between high energy density and traditional sand mill● 通常使用單道次研磨工藝 ● A single pass grinding process is usually used● 特殊的研磨珠保持設計 ● Special grinding bead maintenance design● 特殊之超大篩網(wǎng)清洗設計 ● Special ultra large screen cleaning design● 適用于高磨損產(chǎn)品 ● Suitable for high wear products● 研磨分散大批量涂料 ● Lapping and dispersing large mass paint● 利用離心動態(tài)分離式篩網(wǎng)提高流量 ● Use centrifugal dynamic separation screen to increase flow rate● 容易更換產(chǎn)品接觸部之備件 ● Easy replacement of the spare parts of the contact section of the product

全國熱門有色金屬設備推薦

1042

1042  分享 0

分享 0

舉報 0

舉報 0

收藏 0

收藏 0

反對 0

反對 0

點贊 0

點贊 0