全部

▼

搜索

熱搜:

位置:中冶有色 >

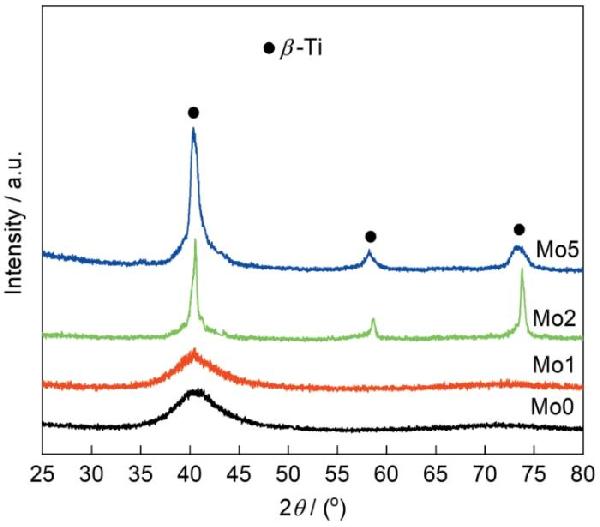

> 原位自生相增強(qiáng)Ti-Zr-Cu-Pd-Mo非晶復(fù)合材料的制備及其力學(xué)性能

533

編輯:中冶有色技術(shù)網(wǎng)

來(lái)源:余圣,郭威,呂書(shū)林,吳樹(shù)森

533

編輯:中冶有色技術(shù)網(wǎng)

來(lái)源:余圣,郭威,呂書(shū)林,吳樹(shù)森

| Sample | E / GPa | σf / MPa | σy / MPa | εf / % | εp / % | n |

|---|---|---|---|---|---|---|

| Mo0 | 122 | 1992 | 1850 | 2.7 | 1.2 | - |

| Mo1 | 128 | 2057 | 1912 | 3.2 | 1.7 | - |

| Mo2 | 113 | 2422 | 1818 | 5.5 | 3.9 | 0.14 |

| Mo5 | 105 | 2630 | 1772 | 9.0 | 7.3 | 0.20 |

分享 0

分享 0

舉報(bào) 0

舉報(bào) 0

收藏 0

收藏 0

反對(duì) 0

反對(duì) 0

點(diǎn)贊 0

點(diǎn)贊 0

中冶有色技術(shù)平臺(tái)

中冶有色技術(shù)平臺(tái) 2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年04月27日 ~ 29日

2025年04月27日 ~ 29日