全部

▼

搜索

熱搜:

位置:中冶有色 >

> C含量對(duì)VCoNi中熵合金微觀組織和性能的影響

860

編輯:中冶有色技術(shù)網(wǎng)

來(lái)源:幸定琴,涂堅(jiān),羅森,周志明

860

編輯:中冶有色技術(shù)網(wǎng)

來(lái)源:幸定琴,涂堅(jiān),羅森,周志明

|

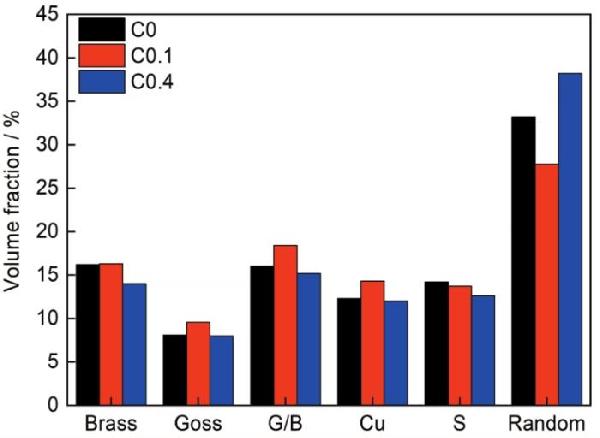

Yield Strength / MPa |

Ultimate tensile strength / MPa |

Elongation / % |

|

|---|---|---|---|

| C0 | 528.30 | 1003.29 | 54.23 |

| C0.1 | 744.62 | 1193.86 | 39.25 |

| C0.4 | 686.68 | 1130.22 | 39.37 |

分享 0

分享 0

舉報(bào) 0

舉報(bào) 0

收藏 0

收藏 0

反對(duì) 0

反對(duì) 0

點(diǎn)贊 0

點(diǎn)贊 0

中冶有色技術(shù)平臺(tái)

中冶有色技術(shù)平臺(tái) 2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年03月25日 ~ 27日

2025年03月25日 ~ 27日