全部

▼

搜索

熱搜:

位置:中冶有色 >

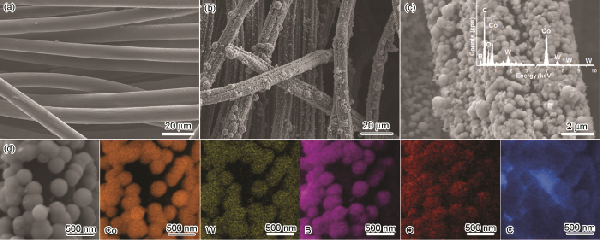

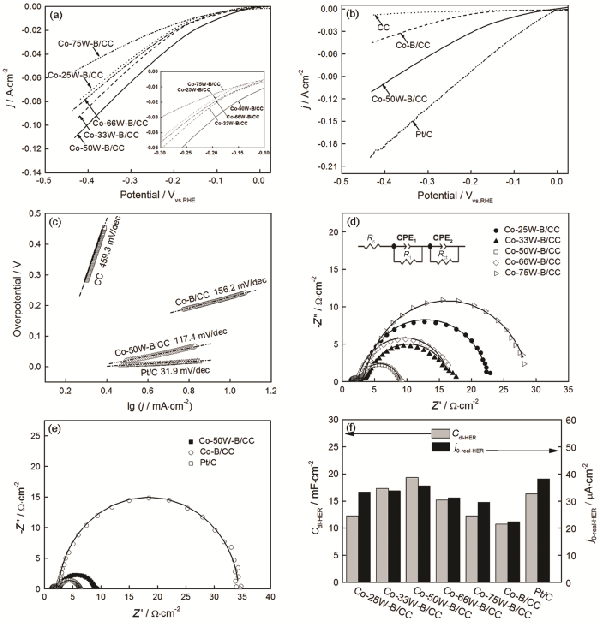

> 非晶Co-W-B/碳布復(fù)合電極材料的制備及其電解水催化性能

924

編輯:中冶有色技術(shù)網(wǎng)

來源:施嘉倫,盛敏奇,吳瓊,呂凡

924

編輯:中冶有色技術(shù)網(wǎng)

來源:施嘉倫,盛敏奇,吳瓊,呂凡

分享 0

分享 0

舉報(bào) 0

舉報(bào) 0

收藏 0

收藏 0

反對(duì) 0

反對(duì) 0

點(diǎn)贊 0

點(diǎn)贊 0

中冶有色技術(shù)平臺(tái)

中冶有色技術(shù)平臺(tái) 2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年03月25日 ~ 27日

2025年03月25日 ~ 27日