全部

▼

搜索

熱搜:

位置:中冶有色 >

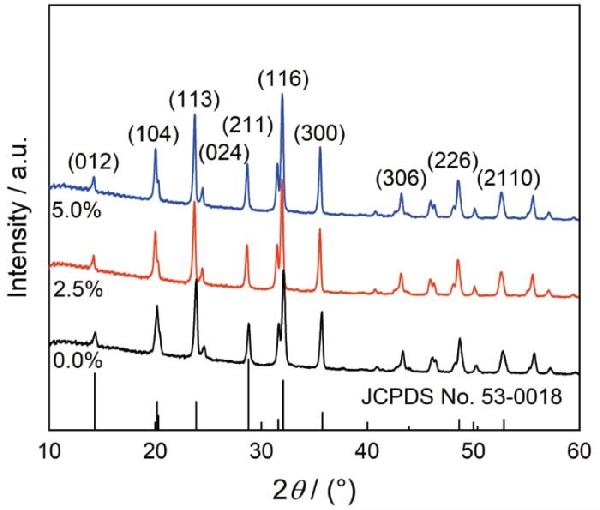

> 鈉離子電池雙層碳包覆Na3V2(PO4)3 正極材料的超聲輔助溶液燃燒合成及其電化學(xué)性能

894

編輯:中冶有色技術(shù)網(wǎng)

來源:羅昱,陳秋云,薛麗紅,張五星,嚴(yán)有為

894

編輯:中冶有色技術(shù)網(wǎng)

來源:羅昱,陳秋云,薛麗紅,張五星,嚴(yán)有為

分享 0

分享 0

舉報(bào) 0

舉報(bào) 0

收藏 0

收藏 0

反對 0

反對 0

點(diǎn)贊 0

點(diǎn)贊 0

中冶有色技術(shù)平臺

中冶有色技術(shù)平臺 2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年03月25日 ~ 27日

2025年03月25日 ~ 27日