全部

▼

搜索

熱搜:

位置:中冶有色 >

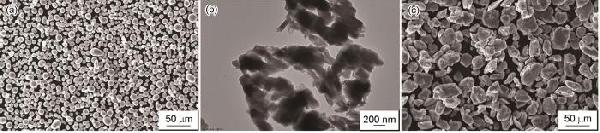

> (Al11La3+Al2O3)/Al復(fù)合材料的高溫性能及其強(qiáng)化機(jī)制

919

編輯:中冶有色技術(shù)網(wǎng)

來(lái)源:周聰,昝宇寧,王東,王全兆,肖伯律,馬宗義

919

編輯:中冶有色技術(shù)網(wǎng)

來(lái)源:周聰,昝宇寧,王東,王全兆,肖伯律,馬宗義

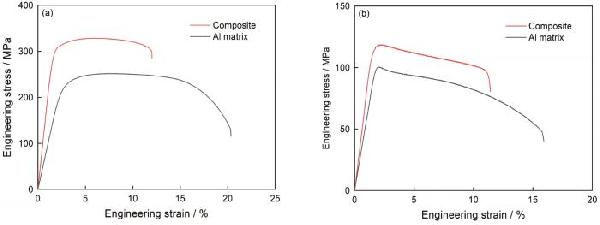

| Sample | RT | 350℃ | ||||

|---|---|---|---|---|---|---|

| YS/MPa | UTS/MPa | EL/% | YS/MPa | UTS/MPa | EL/% | |

| Composite | 292±4 | 328±3 | 10.5±0.9 | 113±5 | 119±4 | 10.2±2.2 |

| Al matrix | 208±8 | 252±3 | 18.5±1.0 | 99±6 | 100±4 | 15.2±2.0 |

| /MPa?σym | Al2O3 | Al11La3 | ||||

|---|---|---|---|---|---|---|

| ?σL-T/MPa |

?σOro /MPa |

?σGND /MPa |

?σL-T/MPa |

?σOro /MPa |

?σGND /MPa |

|

| 10 | 6 | 19 | 26 | 4 | 0 | 11 |

分享 0

分享 0

舉報(bào) 0

舉報(bào) 0

收藏 0

收藏 0

反對(duì) 0

反對(duì) 0

點(diǎn)贊 0

點(diǎn)贊 0

中冶有色技術(shù)平臺(tái)

中冶有色技術(shù)平臺(tái) 2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年03月25日 ~ 27日

2025年03月25日 ~ 27日  2025年04月27日 ~ 29日

2025年04月27日 ~ 29日