全部

▼

搜索

熱搜:

位置:中冶有色 >

> 2101節(jié)鎳雙相不銹鋼立式連鑄板坯的組織轉(zhuǎn)變

904

編輯:中冶有色技術(shù)網(wǎng)

來源:白亮,汲琨,劉景順,劉軍,董俊慧,楠頂

904

編輯:中冶有色技術(shù)網(wǎng)

來源:白亮,汲琨,劉景順,劉軍,董俊慧,楠頂

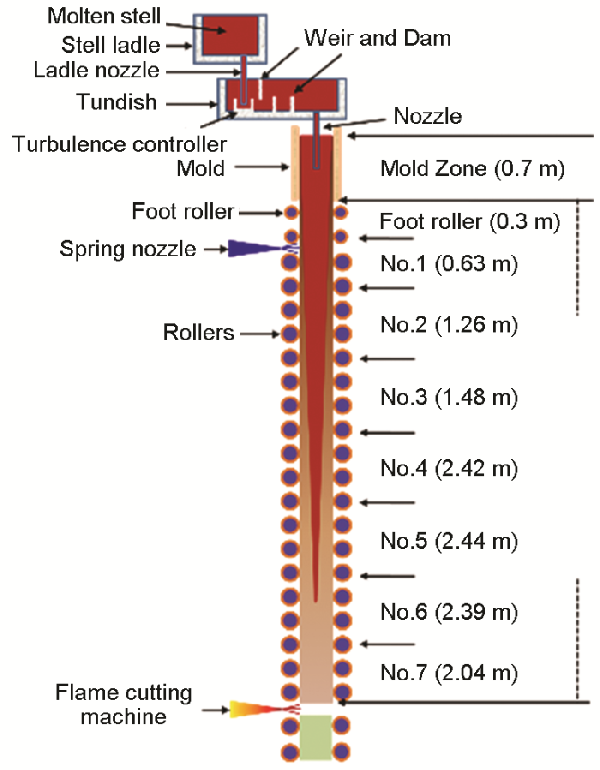

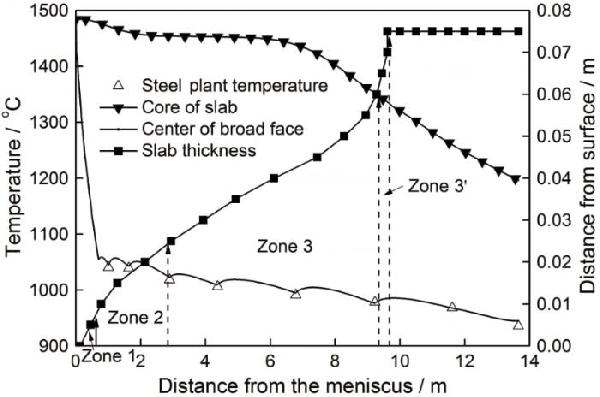

| Location | Mold | Foot roller | No.1 | No.2 | No.3 | No.4 | No.5 | No.6 | No.7 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length/m | Broad | Narrow | Broad | Narrow | 0.63 | 1.26 | 1.48 | 2.42 | 2.44 | 2.39 | 2.04 |

| 0.7 | 0.7 | 0.3 | 0.7 | ||||||||

| Cooling water/L·m-2·s-1 | 2750 | 250 | 8.39 | 4.63 | 3.16 | 2.0 | 0.95 | 0.64 | 0.39 | 0.29 | 0.16 |

| C | Si | Mn | Cr | Ni | Cu | Mo | B | N | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.025 | 0.65 | 5.15 | 21.4 | 1.42 | 0.3 | 0.22 | 0.001 | 0.205 | 0.003 |

分享 0

分享 0

舉報 0

舉報 0

收藏 0

收藏 0

反對 0

反對 0

點贊 0

點贊 0

中冶有色技術(shù)平臺

中冶有色技術(shù)平臺 2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2024年12月27日 ~ 29日

2024年12月27日 ~ 29日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年01月03日 ~ 05日

2025年01月03日 ~ 05日  2025年04月27日 ~ 29日

2025年04月27日 ~ 29日